Effect of size on BDT (brittle to ductile transition) temperature in single crystal silicon

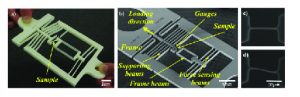

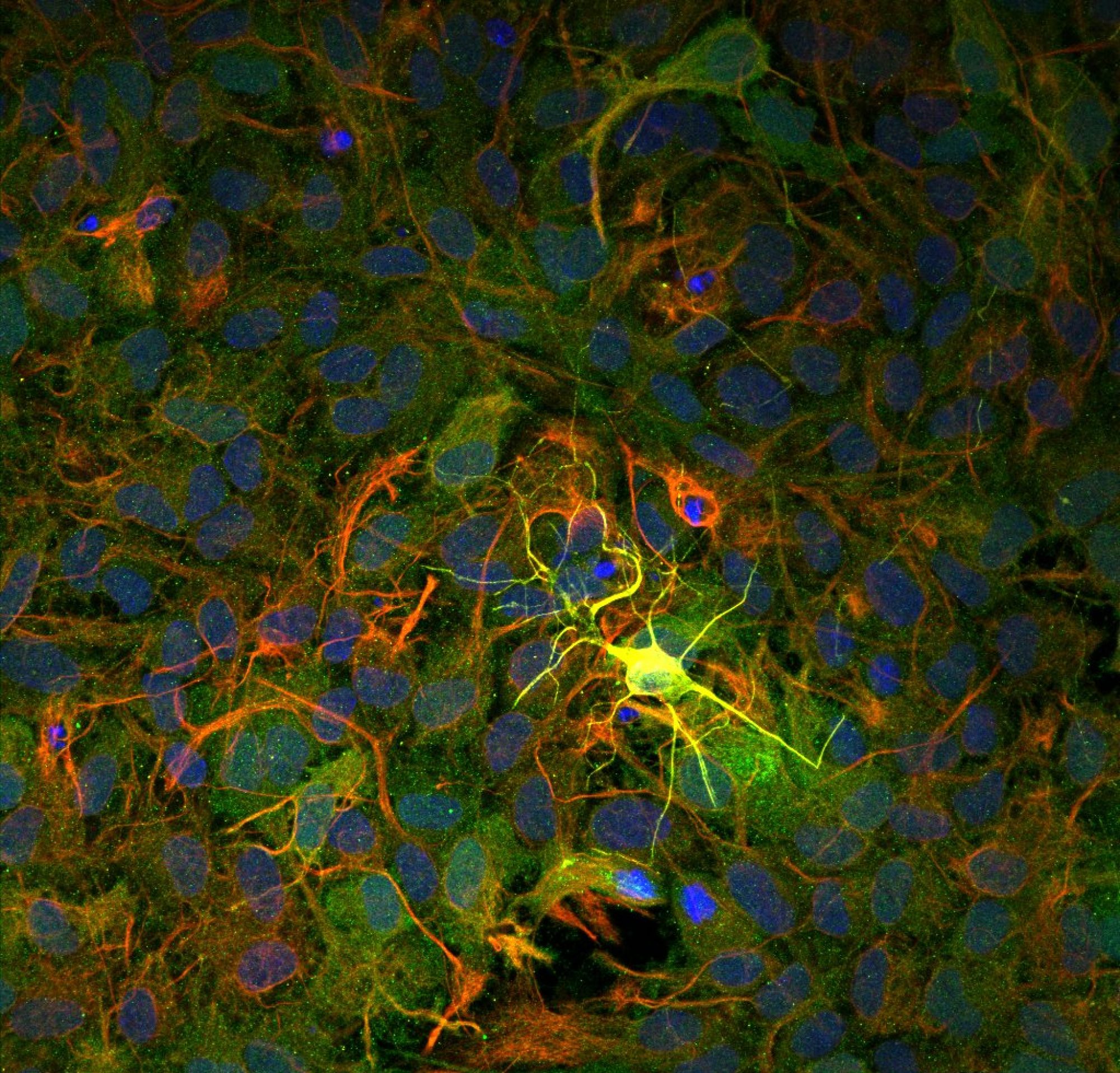

Silicon based micro and nanometer scale devices operating at various temperatures are ubiquitous today. However, thermo-mechanical properties of silicon at the small scale and their underlying mechanisms remain elusive. The brittle-to-ductile transition (BDT) is one such property relevant to these devises. Materials can be brittle or ductile depending on temperature. The BDT occurs over a small temperature range. For bulk silicon, the BDT is about 545°C. It is speculated that the BDT temperature of silicon may decrease with size at the nanoscale. However, recent experimental and computational studies have provided inconclusive evidence, and are often contradictory. Potential reasons for the controversy might originate from the lack of an in situ methodology that allows variation of both temperature and sample size. We resolved this controversy by carrying out in situ thermo-mechanical bending tests on single crystal silicon samples with concurrent control of temperature and size. We showed unambiguously that the BDT temperature reduces with sample size. For example, the BDT temperature decreases to 293°C for a sample size 720 nm. We explained the mechanism by which silicon reduces the BDT temperature with decreasing size. We also developed a mechanism-based model to predict the size dependence of BDT in silicon under bending. We recently completed this project in collaboration with Max Planck Institute, Düsseldorf, Germany (Proceedings of the National Academy of Sciences, July 21, 2020 117 (29) 16864-16871).