We seek to understand phenomena at small scale using the principles of mechanics. We have two research thrusts: mechanics of living cells and tissues (biomechanics), and nanoscale materials (nanomechanics). We use both experiment and theory to address our questions. In order to carry out exploratory experiments, we often develop our own micro and nano-scale apparatus (micro electro mechanical systems, or MEMS), and study their mechanics as well.

Biomechanics/Mechanobiology

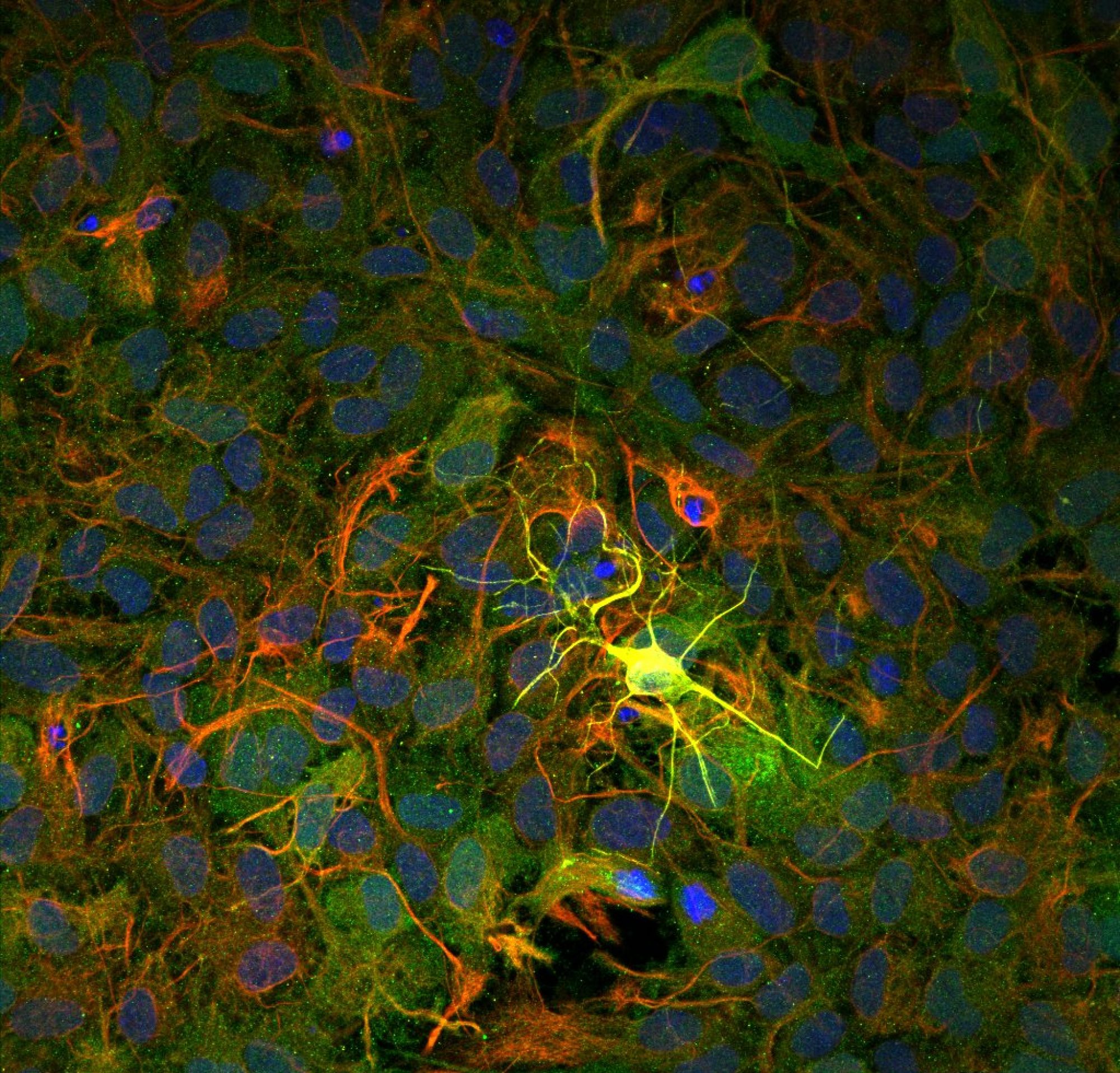

Biomechanics: Cells are basic units of life. There is increasing experimental evidence suggesting that extracellular and intracellular mechanical forces have a profound influence on a wide range of cell behavior such as growth, differentiation, apoptosis (programmed cell death), gene expression, adhesion, and signal transduction. Study of cell mechanics has drawn considerable attention from diverse fields, including biology, physics, biochemistry, bioengineering, and medicine. Our studies of cell mechanics are motivated by three overarching questions: (1) how cells transduce mechanical stimuli into biochemical processes under healthy and diseased conditions? (2) Can disease progression, such as cancer metastasis, be altered with mechanical stimuli? (3) Can cell-cell interaction be engineered to develop new generation of living machines and computers?

Nanomechanics

For a material sample, smallness may appear in various forms, e.g., physical size, layer thickness of a multilayer system, or grain size in a polycrystalline metal. Materials also have interfaces, such as material/air interface, grain boundaries in a polycrystalline material, interface between layers in a composite material. Smaller the size, higher is the interface to volume ratio. At nano scale, interfaces are abundant, and they play important roles in defining macroscopic properties of materials such as mechanical strength, energy dissipation and conductivity. Interfaces interfere with the mechanisms of deformation and transport, and often generate new mechanisms. For example, when large grains of a crystalline metal are sheared, dislocations (crystal defect) can move through the crystal. Dislocation dynamics results in the plastic deformation in the metal. When the grain size is small, grain boundaries impede the dislocations, and change the deformation characteristics and the strength of the metal. On the other hand, single crystal silicon (most used material in micro electronics and micro machines (MEMS)), is brittle at room temperature, but becomes ductile at high temperatures when dislocation avalanche appears – a phenomenon known as brittle to ductile transition (BDT). At small scale, BDT temperature may decrease due to the dislocation avalanche originating from the free surface of the single crystal sample with large surface to volume ratio, and high flaw tolerance of small samples. We address the questions: (1) How does the small size affect thermo-mechanical properties? What is the interaction between the macroscopic mechanisms of deformation and the interfaces at nano scale?

Current projects

Mind in vitro: computing with living neurons

Mechanics of cancer metastasis

Effect of size on BDT (brittle to ductile transition) temperature in single crystal silicon